The Condenser header pipe is one of the important components in the air conditioning system. The role of air conditioning: the fluorine in the air conditioner is compressed by the compressor to produce high temperature and high pressure liquefied gas, which is condensed by the condenser and becomes a low temperature and high pressure liquid, and enters into the Condenser header pipe to be collected.

The Square Rectangular Condenser header pipe have different types of outer diameters and are suitable for different types of air conditioning cooling systems.

1, The type of Square Rectangular Condenser header pipe:

1),Square Condenser header pipe 2), Rectangular Condenser header pipe

Core layer: 3003, 3305

Production Process: high frequency welding, cold drawing

Appearance: can be customized according to customer requirements.

2, The Introduction of the Square Rectangular Condenser header pipe:

Cladding type: single Cladding material, double Cladding material

Cladding layer: 4045, 4343, 7072 anti-corrosion layer

Material Temper: H14,H18,or according to customer requirements;

Cladding rate: 10±2 or according to customer requirements

Core layer: 3003, 3305

Process: high frequency welding, cold drawing

Wall thickness: 1-2.5mm

Appearance: can be customized according to customer requirements,

3.The Product Characteristics of Square Rectangular Condenser header pipe:

1). light weight

2). easy welding

3). Good corrosion resistance

4). Good Voltage Resistance

5). Compliance with standard ROHS

6). High recycling value

7). Small deviation range

8). High surface quality

4, The Usage of Square Rectangular Condenser header pipe:

Square Rectangular Condenser header pipe is used in computer radiators, industrial cooling systems, parallel flow condensers, new energy vehicles, etc.

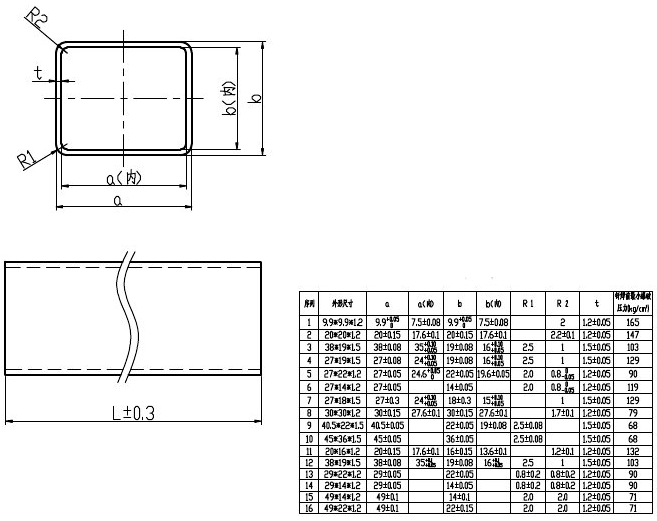

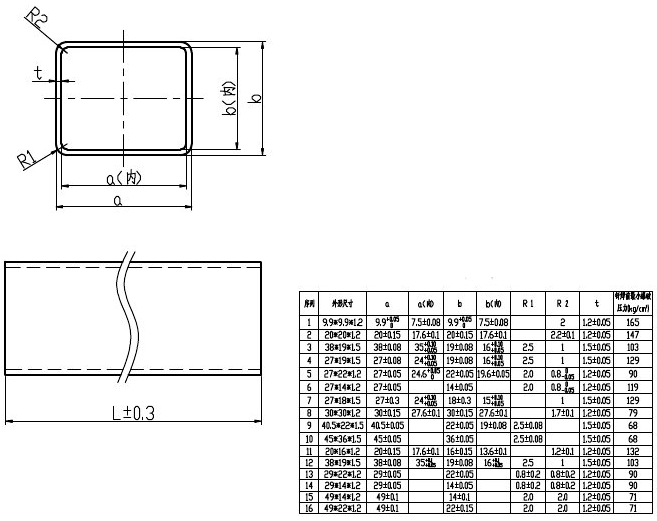

5, The tech requirements and common size of the Square Rectangular Condenser header pipe is shown in the following figure:

1).The cutting end face burr does not exceed 0.2mm,and the inner wall weld line height does not exceed 0.2mm

2).Cutting end face angle 90°+/-2

3).The inner and outer surface of the pipe should be clean and free of foreign matter such as oil,dust and aluminum chips;no defects such as pressure pits,bumps,and scratches are allowed.

4).The length and material of the pipe are customized according to customer’s requirements

5).The existing specifications of our company are shown as below table

The Square Rectangular Condenser header pipe have different types of outer diameters and are suitable for different types of air conditioning cooling systems.

1, The type of Square Rectangular Condenser header pipe:

1),Square Condenser header pipe 2), Rectangular Condenser header pipe

Core layer: 3003, 3305

Production Process: high frequency welding, cold drawing

Appearance: can be customized according to customer requirements.

2, The Introduction of the Square Rectangular Condenser header pipe:

Cladding type: single Cladding material, double Cladding material

Cladding layer: 4045, 4343, 7072 anti-corrosion layer

Material Temper: H14,H18,or according to customer requirements;

Cladding rate: 10±2 or according to customer requirements

Core layer: 3003, 3305

Process: high frequency welding, cold drawing

Wall thickness: 1-2.5mm

Appearance: can be customized according to customer requirements,

3.The Product Characteristics of Square Rectangular Condenser header pipe:

1). light weight

2). easy welding

3). Good corrosion resistance

4). Good Voltage Resistance

5). Compliance with standard ROHS

6). High recycling value

7). Small deviation range

8). High surface quality

4, The Usage of Square Rectangular Condenser header pipe:

Square Rectangular Condenser header pipe is used in computer radiators, industrial cooling systems, parallel flow condensers, new energy vehicles, etc.

5, The tech requirements and common size of the Square Rectangular Condenser header pipe is shown in the following figure:

1).The cutting end face burr does not exceed 0.2mm,and the inner wall weld line height does not exceed 0.2mm

2).Cutting end face angle 90°+/-2

3).The inner and outer surface of the pipe should be clean and free of foreign matter such as oil,dust and aluminum chips;no defects such as pressure pits,bumps,and scratches are allowed.

4).The length and material of the pipe are customized according to customer’s requirements

5).The existing specifications of our company are shown as below table